inquiry

Co-Engineering the Future of Battery Technology

We go beyond standard manufacturing to become your strategic partner in power innovation. Our advanced prismatic cell OEM and custom development services are designed for clients with unique performance, size, or integration requirements. From initial concept to mass production, our engineering team works closely with you to create a tailored cell solution that provides a competitive edge to your end product.

Key Features:

Full Customization Capability:

Tailor dimensions, capacity, energy density, internal resistance, and terminal type to your exact specifications.

Advanced Chemistries:

Expertise in leveraging cutting-edge anode and cathode materials to achieve target performance metrics.

Joint Development Process (JDP):

Collaborative approach from design and prototyping to testing and volume production.

Dedicated Engineering Support:

A team of battery experts assigned to your project to ensure technical success.

Pilot Run and Validation:

We support small-batch pilot runs for thorough testing and validation before mass production.

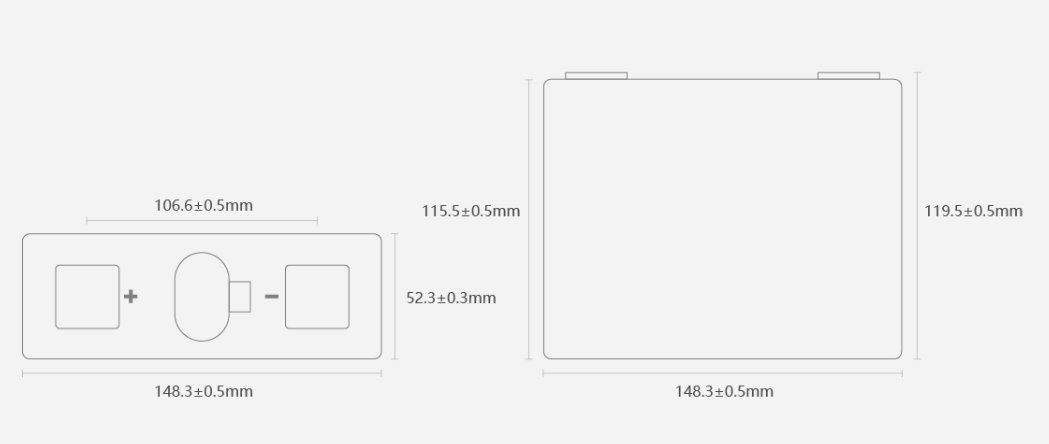

Dimensions:

Major Technical Parameters:

| HCLFP106 | |||

| Item | Standard | Note | |

| Standard Capacity | 106Ah | 0.5C | |

| Minimum Capacity | 106Ah | 0.5C | |

| Standard Voltage | 3.2V | ||

| Alternating Internal Resistance | 0.2-0.4mΩ | ||

| Charge Conditions | 3.65±0.05V 0.01C | 3.65±0.05V 0.02C | Constant-current charge to 3.65V at 0.5C, constant voltage charge to stop until 0.02C mA |

| Standard Charge Current | 0.2C | ||

| Max. Charging Current | 1C | ||

| Discharge Cut-off Voltage | 2.0V | ||

| Standard Discharge Current | 0.5C | ||

| Max. Continuous Discharge Current | 2C | ||

| Pulse Discharge Current | 3C, 30s 4C, 10s | ||

| Cycle Characteristic | 4000 times (90%DOD) 6000 times (80%DOD) | The residual capacity is no less than 80% of rated capacity at 0.5C rate | |

| Working Temperature | Charge: 0℃~55℃ Discharge: -20℃~60℃ | ||

| Storage Temperature | -20℃~45℃ | Short-term storage (< 1 months) | |

| Cell Weight | <1935±30g | ||

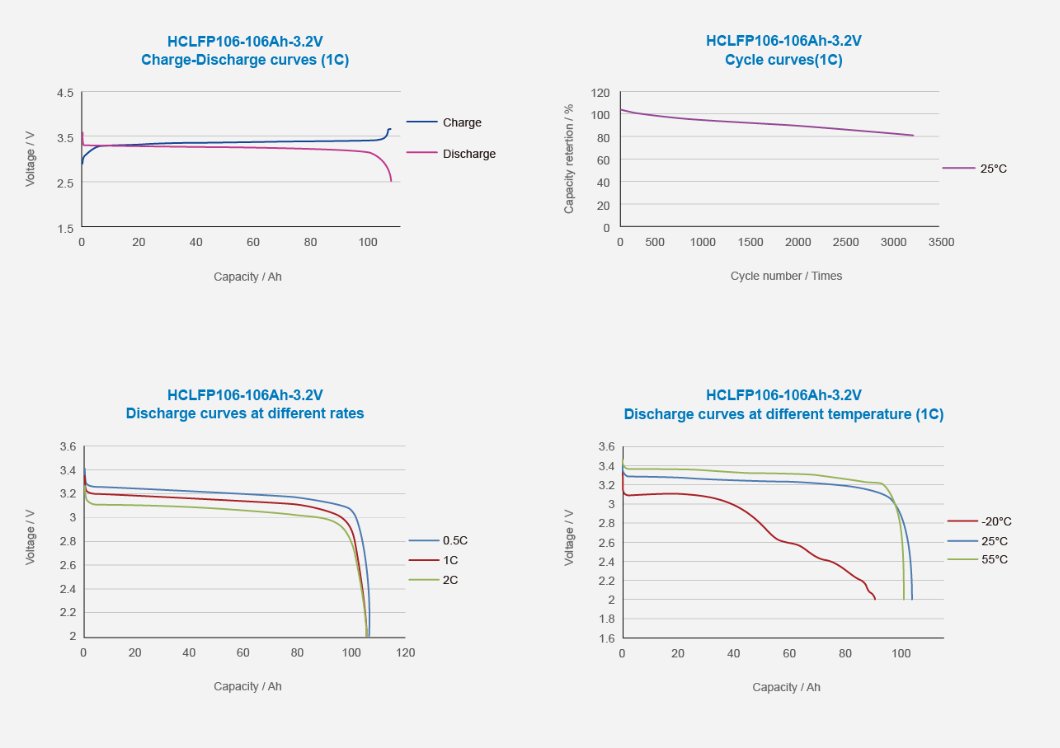

Characteristics Curves:

Applications:

● Co-development for Specific EV Models

● Custom Power Solutions for Premium Consumer Electronics

● Custom Packs for Electric Tools and Appliances

● Tailored Energy Storage Solutions for Large-Scale Projects

Ready to Upgrade Your Power?

[➔ Download the Full Specification Sheet (PDF)]

[⮟ Contact Our Experts for a Quote]

| HCLFP106 | |||

| Item | Standard | Note | |

| Standard Capacity | 106Ah | 0.5C | |

| Minimum Capacity | 106Ah | 0.5C | |

| Standard Voltage | 3.2V | ||

| Alternating Internal Resistance | 0.2-0.4mΩ | ||

| Charge Conditions | 3.65±0.05V 0.01C | 3.65±0.05V 0.02C | Constant-current charge to 3.65V at 0.5C, constant voltage charge to stop until 0.02C mA |

| Standard Charge Current | 0.2C | ||

| Max. Charging Current | 1C | ||

| Discharge Cut-off Voltage | 2.0V | ||

| Standard Discharge Current | 0.5C | ||

| Max. Continuous Discharge Current | 2C | ||

| Pulse Discharge Current | 3C, 30s 4C, 10s | ||

| Cycle Characteristic | 4000 times (90%DOD) 6000 times (80%DOD) | The residual capacity is no less than 80% of rated capacity at 0.5C rate | |

| Working Temperature | Charge: 0℃~55℃ Discharge: -20℃~60℃ | ||

| Storage Temperature | -20℃~45℃ | Short-term storage (< 1 months) | |

| Cell Weight | <1935±30g | ||

Our cells incorporate multiple safety features, including proprietary electrode coatings to prevent dendrite formation, built-in CID (Current Interrupt Device) for overpressure protection, and ceramic separators that withstand high temperatures. Each cell undergoes rigorous testing including nail penetration and overcharge tests.

Under standard conditions (25°C, 80% DoD):

LiFePO4 cells: 3,000-5,000 cycles with ≥80% capacity retention

NMC cells: 1,500-2,000 cycles with ≥80% capacity retention

Actual lifespan depends on operating temperature, discharge rates, and maintenance practices.

All cells meet international standards including UN38.3, IEC62619, and UL1642. Our manufacturing process is ISO9001 certified, with complete traceability from raw materials to finished products. Each batch undergoes comprehensive testing including cycle life, internal resistance, and thermal stability assessments.